DESIGN AND DEVELOPMENT OF AN INTELLIGENT UV SANITISING SYSTEM FOR BOTTLE BEVERAGES

Within the hospitality sector, a large number of beverages are consumed from the neck of glass bottles (approx. 30%). Prior to the Covid-19 pandemic, there was already a growing need to address the cleanliness of these glass bottles for the health and safety of the consumer. As we slowly edge back to normality that needs will be greater than ever!

Glass bottle tops, especially under the cap, are breeding grounds for bacteria and viruses. Bottles are usually visually clean but not sanitised. For the complete sanitisation of the bottleneck, the cap needs to be fully removed. Inferneco, a Wicklow based start-up have identified a potential solution to this problem using UV light.

Specifically, this project involved using UV-C light to achieve the required results. The benefits of UV-C light being used against unwanted microorganisms is already well proven and it has the capability to disinfect and eliminate up to 99% of germs, viruses and bacteria. Research is ongoing in regards to UV’s capabilities in fighting Covid-19 however there is optimism and early signs that devices like this can have a positive effect.

To turn their idea into reality, Infeneco teamed up with the Technology Gateway Network to avail of some of the funding mechanisms that are easily available for companies willing to experiment in R&D and Blue Ocean strategy. The potential of the product was clear from the outset and it was evident that a deeper level of financing would be needed so an Enterprise Ireland Innovation Partnership, led by Design+ in IT Carlow was used to develop the project further.

The first phase of the project was to examine and explore other possible solutions to sanitising and in turn define a clear direction for the design of a new concept. The new concept had to be able to sanitise a bottle within two seconds and also needed to include a safe sealing system so as not allow the user to be exposed to any UV light.

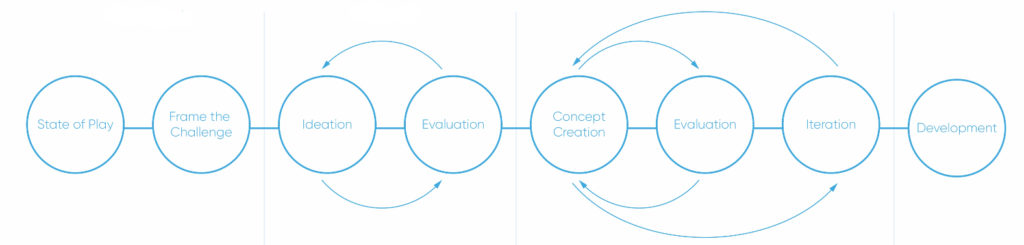

Design+ followed their bespoke innovation process and the following ideation and evaluation sessions came up with the most suitable prototype, the purpose of which was to test and validate the concept.

Above: The Design+ Innovation Process

Left: First 2 prototypes, developed for testing, on a display stand. Right: Prototype showing functionality

The housings for the prototypes were all 3D printed inhouse using IT Carlow’s class-leading 3D printers. This allowed them to iterate quickly and produce high-quality models that were able to withstand the testing phase which was performed in the environment of a busy pub/nightclub. The unit’s electronics were also designed and built by the Technology Gateway team within the Institute.

The test results were positive for sanitizing the bottle in two seconds and feedback from the user was excellent. Following further on-site testing, the design was revised and more iterations/updates were created to advance the system, such as improved bottle chamber design, better reflectors and seals in the light chamber. A new 3D printing resin with improved thermal and mechanical performance was also used and proved to be very beneficial at this phase.

Overall the project was a success and collaboration with other Technology Gateways was key to this achievement. During the testing phase, the prototype was sent to the CAPPA Gateway in CIT who proved that the system could sanitise the bottle in two seconds and that there was no UV exposure to the user, these were the two main objectives of the project. The Design+ team also worked alongside the TSSG Gateway in IT Waterford. The team there were instrumental in helping Design+ to create a Windows-based User Interface (UI) application that increased the devices functionality.

To find out more about DESIGN+ Technology Gateway, contact them via email and follow them on Twitter for all the latest news.